Splash Fills

Film types fills have been popular with the Cooling Tower Industry as a resuit of their efficiency of not only handling large quantities of water but also the overall tower efficiency, However in the case of heavily contaminated water, film type fills are susceptible to accumulating deposits and often make way for the use of splash type fills for effective water cooling. The forgiving nature of splash fills towards ‘dirty’ water and imperfect water distribution is offset by the need to have larger towers and thus higher capital costs as well as pumping heads.

Splash fills work on the principle of causing the flowing water to fall through a grid of "splash bars/grids" causing the water droplets to break up and increasing the contact time between water and air, As the falling water encounters multiple layers of these splash fills, the droplets keep dividing into smaller sizes thereby increasing the heat transfer and thus cool the water.

AMARTAL has a range of products in the Splash type fill environment, including V-Bars, Perforated Slats, Triangular Bars, Rectangular Slats, and Polypropylene grid fills. Our engineers can recommend the right solution for your applications.

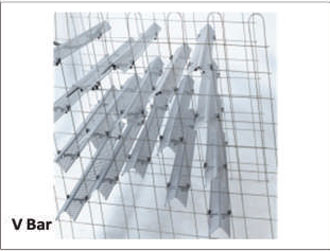

Perforated V-Bar

The most extensively used splash bar in the industry. Highly popular with crossflow towers, the fill has now been effectively used in large counterflow NDCT as weil. The standard sizes as well as the standard diamond shape perforations in the 'V' Bar ensure the cooling tower to perform as published in the CTI bulletins — particularly for the configurations - 8" x 8" perpendicular to airflow, 8" x 8" parallel to airflow and 16" x 8" parallel to airflow. This enables the Cooling Tower designer/user to have the complete information about calculating the thermal capabilities of the cooling tower along with its power requirements. These Splash Bars are supported on lightweight thin section grids.

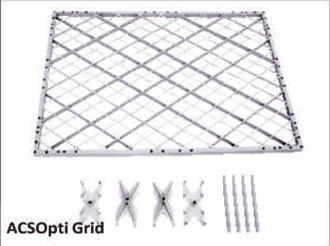

ACSOpti grid

One of the most efficient splash fills for counterflaw cooling towers is the ACSOpti grid fill. Injection moulded using Polypropylene, this grid fill allows the cooling tower designer to optimize on the tower height in a splash fill designed counterflow cooling tower. AMARTAL offers the entire grid fill system including the grid fill, spider, distance tubes and the SS wire along with the clipping accessories.