Drift Eliminators

Drift eliminators are used to capture water dropiets in the air stream that otherwise would be lost to the atmosphere. Entrapping these droplets is important for not only conserving water as a resource but also to prevent cooling tower water from contaminating the area peripheral to the cooling tower. The cooling tower industry uses drift rate to compare drift eliminator performance, a relationship that correlates droplet capture efficiency to the water circulation rate ina tower.

PRINCIPLE OF WORKING

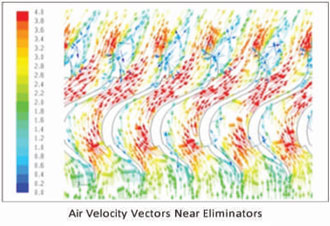

Drift eliminators work on the premise of using inertial separation caused by the exhaustive flow direction changes wnile passing through the drift eliminator, This creates centrifuga! forces on the drift droplets, forcing them to be captured by impaction and direct interception. The directional changes cause the air and water to separate: the air following the aerodynamic path of the blade while the water impinging the surface of the adjacent blades and being channeled back into the system.

As illustrated in the figure, the outgoing air is first guided on to the surface of the drift eliminators. This drift laden air then traverses the upward path of the drift eliminator. At the point of the first direction change ACSDrif—El146 introduces a water entrapment notch. A majority of water droplets are trapped at this notch and channel back Into the system.

Untike other drift eliminators, where water entrapment areas lead to increase in pressure drop, the path te air velocity remains sinusoidal, Thereby introducing little to no additional pressure drop at this point.

The air with the remaining drift droplets undergo another direction change and encounter the surface of the adjacent blade. The system continues to work on the principle of inertial separation. At the exit of the drift eliminator, the air undergoes a third direction change while the water droplets encounter a second notch, which entraps a majority of the drift droplets and brings them back into the system. Some other commercial crift eliminators have a rather large bulb at the exit of the drift eliminator, where most of the drift elimination is performed. These eliminators are not designed to optimize the use of the entire drift eliminator depth and the large bulb introduces a rather large static pressure in the cooling tower.

AMARTAL's drift eliminators are specifically designed to achieve maximum drift removal efficiency in both crossfiow and counterflow tower applications with various product options available to minimize pressure drop, drift loss, cost, of acombination of all three.

AMARTAL offers broadly two types of Drift Eliminators a) Cellular b) Blade

BLADE DRIFT ELIMINATORS

AMARTAL's extruded blade drift eliminators use a series of sinusoidal-shaped PVC blades that force air to make three distinct changes of direction for maximum drift removal. As cost-effective drift removal options, the heavy gauge blades are held together with blade spacers to form a module that is lightweight yet strong enough to span upto 2400mm thus saving material and labour costs.

Amartal Drift Eliminators are highly resistant to chemical & biological degradation. Strong alkalis and acids and salt solutions have negligible effect an durability & strength. This results in a long life for drift eliminator.